OUR PLAN FOR SUSTAINABILITY

Our daily commitment is formed of concrete actions for social and environmental sustainability, founded on an ESG plan aligned with the UN Sustainable Development Goals.

The enhancement of quality is an objective that ICA pursues on a number of different levels, through the quality-focused innovation of its products and services; the commitment to full utilization of the expertise of its human resources; the winning of substantial market share both domestically and internationally; the achievement of maximum customer satisfaction; and the constant reduction of the environmental impact of its coatings.

We embarked with a dream, which we have transformed into a global reality. With determination, perseverance and commitment, we have explored new territory, savoring the challenges and the unknown.

ICA is a large Italian company with headquarters in Civitanova Marche (Macerata). In December 2022, it joined the wood division of The Sherwin-Williams Company, a global leader in the coatings industry, founded in 1866 and operational in 120 countries.

Today, it can therefore count on the strength of a Group that explores new horizons; the strength needed to satisfy a demanding and rapidly evolving market requiring innovative, high-quality and environmentally friendly solutions.

One of ICA’s main strategic assets is the fact that its corporate culture is based on a commitment to achieving maximum quality through innovation. This principle has underpinned the group’s every initiative and strategic decision from the very beginning, thus guaranteeing the development of products that are at the cutting edge, both in terms of quality and in terms of technology.

The R&D department comprises a number of lab teams, in which chemists, researchers and analysts co-operate and interact closely. The R&D operations are targeted, in the main, at coatings, pigments, stains and impregnating agents, but also at quality controls on raw materials and finished products with a view to conducting the practical tests that will determine their suitability to the various application systems.

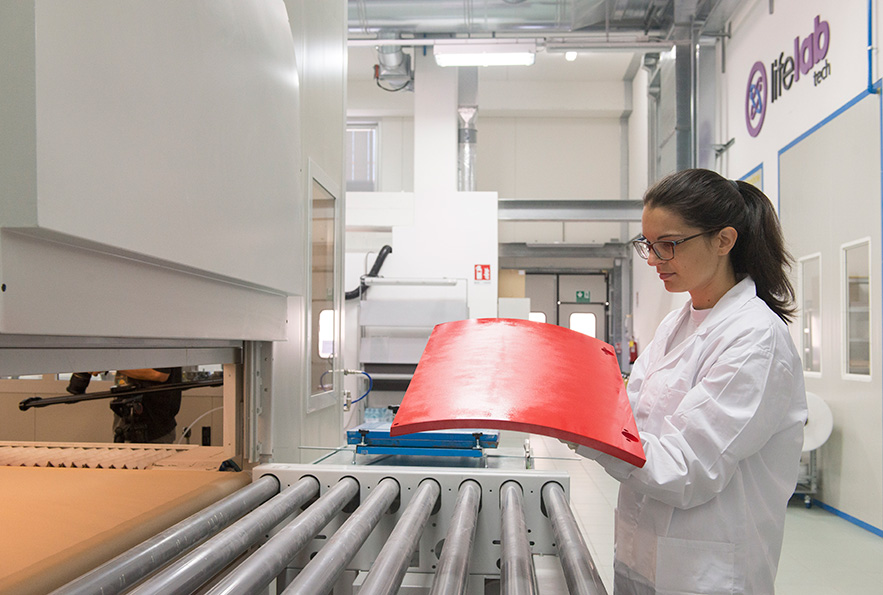

Lifelab is a laboratory entirely dedicated to our customers, designers and planners. A place for gathering inspiration and carrying out tests where we put technology, knowledge and research at your disposal.

In the "tech" area we have created a space with the most advanced coating systems to personally assess the performance of our products.

The "discovery" space is instead a mix of creativity and interior design solutions. A place where you can see colors and trendy effects and touch different materials and shapes.

PRODUCTION CYCLE

At the production plant in Civitanova Marche, the manufacturing cycle is highly automated. It uses computerized systems that ensure perfect replicability of the production recipes, precision weighing of the different substances involved in the production cycle and maximum safety in the handling of dangerous substances. All of this, in turn, guarantees the quality of the finished product, although – against a backdrop of ever-increasing automation – the checks carried out by the operators, who are knowledgeable, experienced and extremely attentive, remain essential.

Once the production phase per se has been completed, tests are conducted on each batch in order to verify that the product corresponds to the stated requirements. If the coating passes these quality-control tests, it is ready to be filtered and packaged for sale.

LOGISTICS

The warehouse in Civitanova Marche for the storage of finished products is the group’s outgoing logistics center, where products that have been sold are sorted in preparation for dispatch to the clients and stock is sent out to the depots and branches (which are located both within Italy and further afield). The facility makes it possible to accelerate the pace of the shipping, standardization and storage operations, minimize the order lead times, manage the packaged batches and optimize the supply levels. In addition, it also provides all-important real-time access to the inventory held at the central facility and at all of the branches.

ICA Group has always been able to guarantee high standards in terms of its short lead times and on-time deliveries, thanks also to this innovative logistical infrastructure.